I was recently lucky enough to visit Cheddite and Nobel Sport in France. I was taken through the production of shotgun cartridges from start to finish and it proved to be enlightening. I have been involved in the production of 12g ammunition for several years but the components were outsourced. I had never considered the attention to detail that goes into the manufacture of plastic cartridge cases for example.

Cheddite produces about a quarter of the worlds primed shotgun cartridge cases. They supply to some of the biggest brands in the industry. If you have spent a few days shooting shotguns, it is likely you have used Cheddite products without even realising it. The first thing I noted was the size of the case manufacture lines, it quickly became apparent why. Bags of plastic chippings are poured into a machine that then heats them up and extrudes them. The result looks rather like a thick-walled garden hose. The hose is then fed in a long line through multiple heating and cooling stations where it is further stretched and shaped, hence the length of the line. Each station generates data which ensures that the dimensions are within tolerance. At the end of the line the hose is now recognisable in size and thickness as a cartridge case. It is then stored on huge rolls until the next stage of manufacture takes place. There are many colour options from translucent through to pinks and purples.

The hose is then cut into precise lengths and now starting to look a little more familiar. Meanwhile the case heads are being formed from flat sheets of metal. Again, the dimensions are checked digitally during the process to ensure the products meet stringent quality standards. The case heads are stamped from a mind-boggling array of recognisable brand options. Finally, a plastic buffer piece is inserted to add strength and integrity to the case head.

The case head and plastic case are bonded together. The bond is incredibly strong and, in most cases, watertight (although that is not part of the required specification). Finally, the cartridge passes through a priming machine where the 209 primer is inserted into the pocket. A specified number of complete articles are then taken in batches of 25 and placed in a primer sensitivity rig. They are all hit at once by firing pins which produce an exact amount of kinetic energy. Should any fail to function, the production would be stopped and investigated to find out what had caused the problem.

These completed cartridge cases are boxed up where they will make their way to one of the manufacturers which was my next stop.

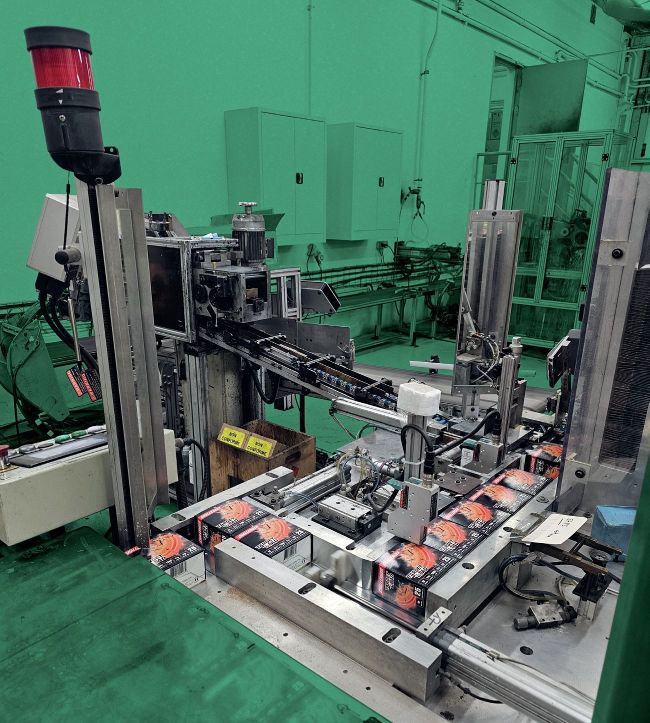

Nobel Sport France make a huge volume of their own 12g cartridges along with products for third party brands. They have just about every sporting cartridge option within their catalogue. The production line is mesmerizing to watch. The cheddite cases are fed into huge in-trays along with wads, spacers and of course the propellant. As the cases travel down the line the components are fed in one by one. The propellant is accurately dosed first. This step is vital as it will define the performance of the cartridge and the safety. The propellant dosing stage is regularly checked and weighed to ensure all is as it should be. Next a wad is pressed in, either plastic or fibre followed by the pellets. Steel makes up much of the production as most of Europe now has strict laws regarding lead pellets. The guys in France certainly had no complaints when I asked them about steel vs lead. For most, lead had already become a distant memory and they were very happy with steel for both clays and hunting. Of course, there are other more expensive options such as bismuth, copper and even tungsten but these are produced in much smaller quantity due to high material price.

The packaged cartridges, ready to go

Cheddite produces about a quarter of the worlds primed shotgun cartridge cases.

I saw some very interesting products which I have not used here in the UK. One was a wad with four definitive chambers in it (split like a cake). I asked what benefit this had and was told with no sign of humour that it was for people who are not very good at shooting – it has a very wide spread! Once the pellets and any spacers have been dropped in, the crimping process begins. Dies begin to shape the bottom of the cartridge into a star crimp which effectively seals all components in place and prevents to some degree any ingress from the environment. The completed cases trundle down the line to the packing section where they are dropped into boxes 25 at a time. These inner packs are then put into outer boxes and finally onto pallets ready to be moved off site to suppliers.

The most interesting thing I found out was that the quality control never changes. From the cheapest product through to the most expensive they all undergo the same rigorous quality testing. Buying expensive may give you some premium components but it does not affect quality checks at all. The sheers scale of these operations and the intensity of quality adherence makes you wonder how shotgun cartridges remain so cheap (even though most customers complain they are too expensive). It gave me renewed respect for the product itself and the manufacturers who work on a high-volume low margin basis.